Numerical control steel bar truss welding production line Product synopsis The numerical control steel bar truss welding production line is set wire rod raw material puts the line, the steel bar strightening, the curving forming, the automatic welding, decides the ruler cut-off and the end product numerical control transportation's entire automatic production line. Widely applies in the high-speed railroad, professions and so on building construction. For example: On high-speed railroad double type railroad tie truss and building structural purpose building carrying plate truss.

Technical parameter

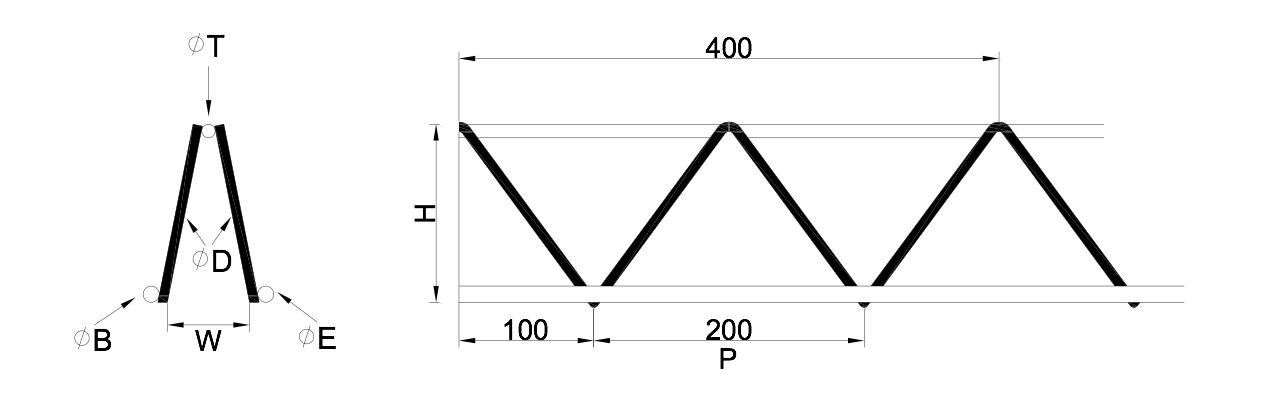

| Model | HJ-70-300 |

| Welding speed | 12-18 [m/min.] |

| Electrode quantity | 4Wrap(Two-row) |

| Truss depth(H) | 70-300 [mm] |

| Truss width(W) | 50-100 [mm] |

| Above main reinforcement diameter(φt) | φ5-φ12 [mm] |

| Following main reinforcement diameter(ØB) | φ5-φ12 [mm] |

| Wave steel bar diameter(ØD) | φ5-φ8 [mm] |

| The wave is apart from (P) | 200 [mm] |

| Power source requirement | 380V 50Hz 90KVA |

| Power consumption | 10-60 [KV] |

| Is mad the source requirement | 0.7MPa 3m3 /Minute |

| Biggest welding ability | φ8+φ12 [mm] |

| Wire material | Iron wire |

| Steel wire surface condition | Clean refacing or galvanization steel wire |

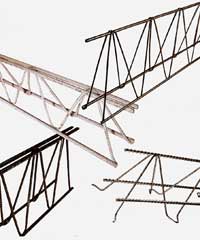

Steel bar truss end product

Steel bar truss welding production line

Steel bar truss template

Truss

Truss product chart